Precision CNC, without the surprises.

Prototypes to production — with dependable timelines and clear communication.

Onewell Tech Inc. is a focused machining partner based in Oakville. We blend machinist judgment with modern methods to deliver production-ready parts, fixtures, and practical process improvements. From first prototype to repeat production, our goal is simple: dependable timelines, clear communication, and parts that arrive ready to work.

We start with a straightforward feasibility and manufacturability review, offering input that reduces risk and shortens lead time. During the build, we keep you informed at defined milestones—no guessing. On request, we provide inspection and documentation, and we capture lessons learned so each subsequent run is smoother than the last.

Our capabilities span aluminum, steels, stainless, tool steels, and engineering plastics, with the ability to hold ±0.005 mm when the process demands it. We handle small batches through production quantities, design and manufacture fixtures for repeatability, and support hydraulic/pneumatic systems—design and repair—to minimize downtime and keep your line moving.

Our team combines CNC milling and turning, fixture & tooling design, and process optimization to improve throughput and quality. We machine a wide range of metals and plastics and can maintain ±0.005 mm where required. We also service hydraulic and pneumatic systems to keep operations running smoothly.

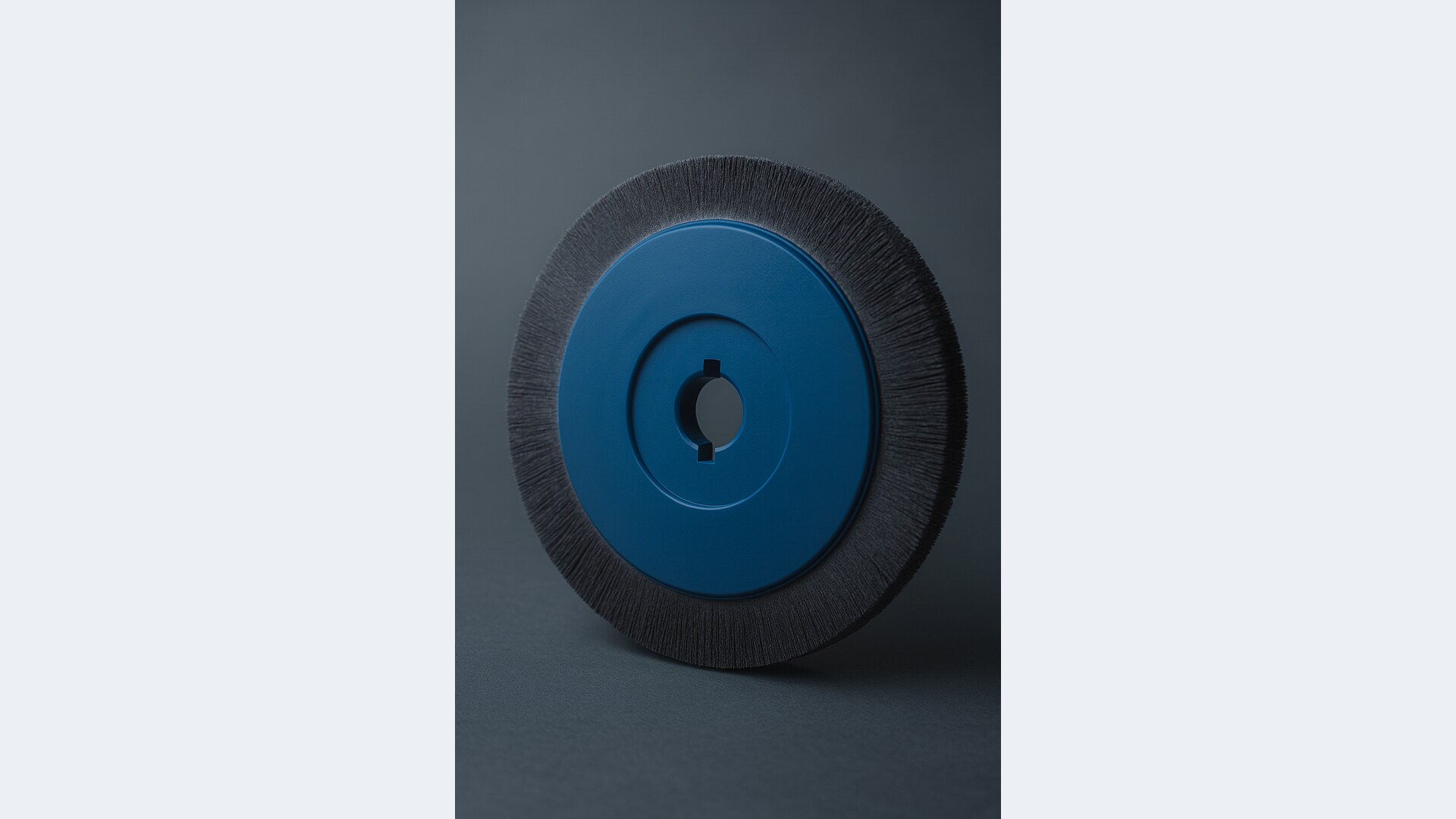

Milling, turning, grinding — built for uptime and repeatability.

Optimization, stabilization, and cost savings grounded in shop-floor reality.

Design and manufacture of custom fixtures and tooling for repeatable results.

System design, repair, and services to keep production moving.

Clear steps so you always know what’s happening.

Share drawings and timing; we confirm feasibility and lead time.

We machine, inspect, and communicate key milestones.

Parts ship with requested documentation; notes for next run.

Ready to move fast with fewer surprises?

Contact Onewell Tech